客服电话

0571-63599807

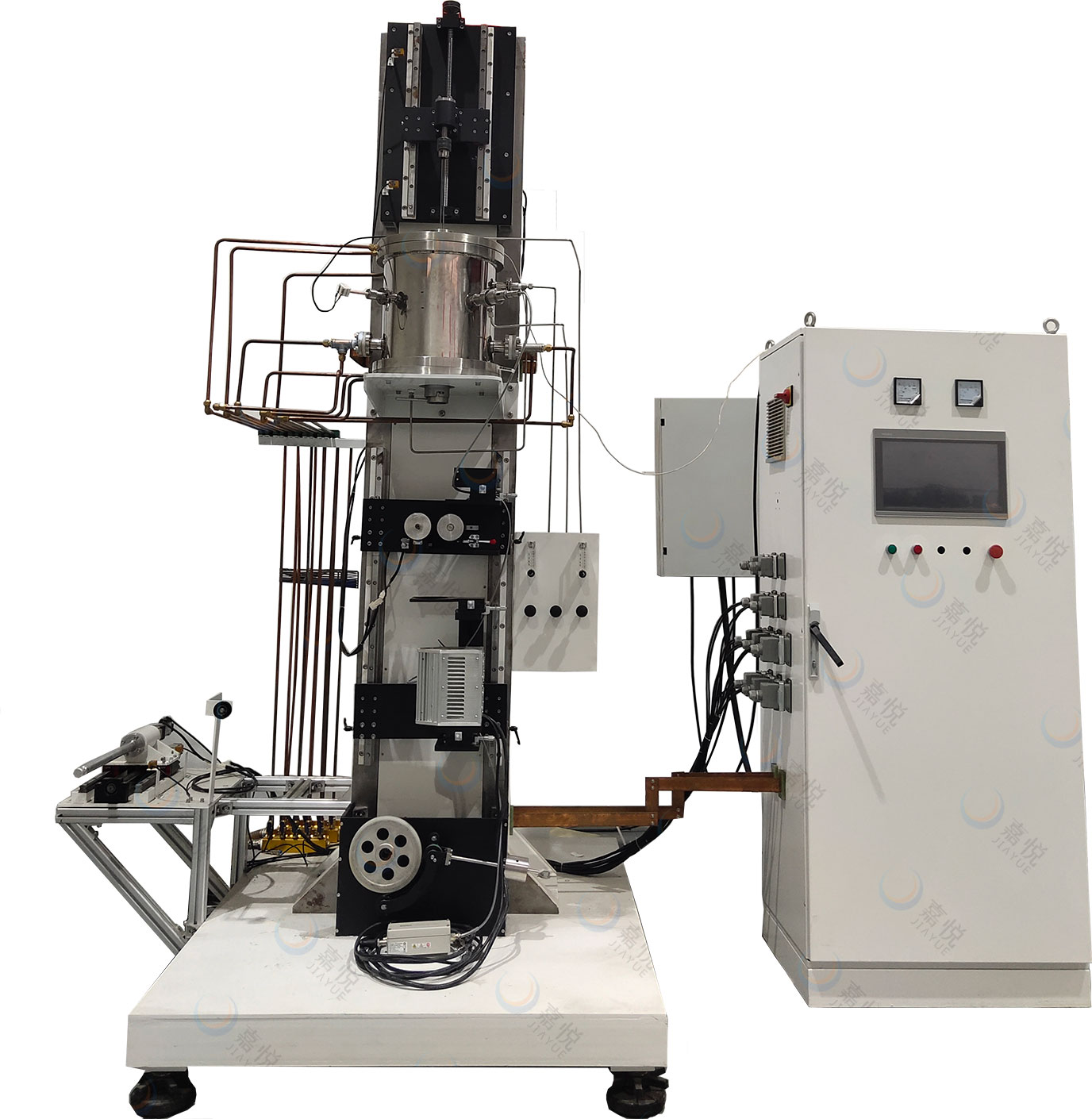

I、Product Introduction

The drawing tower is suitable for manufacturing small complete sets of drawing equipment for single-mode, multi-mode optical fibers, special optical fibers and other optical fibers. It is mainly composed of tower, heating mechanism, traction mechanism, measuring mechanism, wire take-up mechanism, control mechanism and other modules to realize the development and production of various types and structures of special high-temperature quartz fibers.

II、Product Features

1. Servo mechanism is adopted for the feeding mechanism to precisely control the lowering speed of preform;

2. The heating part adopts high-strength graphite heating furnace, which can be controlled under high temperature) to achieve the purpose of safety, convenience and economy;

3. The traction mechanism adopts AC servo control and high-precision reducer to control 6-wheel synchronous vertical traction. In order to meet the production needs of drawing multi specification capillary tubes. The drawing speed can be as low as 1m / min;

4. The wire take-up mechanism is designed to match the wire take-up wheel and the dancing wheel to facilitate the synchronization of wire take-up and traction;

5. Multiple safety protection design, sound and light alarm, water and gas cut-off automatic boiler shutdown, etc., to realize stable operation of equipment;

III、General technical parameters of equipment

| 1 | Heating power | ~ 3KW |

| 2 | Voltage | 220V / 50Hz |

| 3 | Length of heating section | 3 * 100mm |

| 4 | Number of heating sections | 3 sections, each section is independently controlled |

| 5 | Heating element | high temperature alloy wire |

| 6 | Maximum operating temperature | ≤ 1200 ℃ |

| 7 | Diameter of preform | Φ 10~ Φ 40mm |

| 8 | Travel of preform | 400mm |

| 9 | Rod feeding speed | 0.05 ~ 10mm / min |

| 10 | Wire drawing speed | 1 ~ 15m / min |

| 11 | Overall dimension of equipment | Main Tower 2000 * 1500 * 4500mm, electric control 600 * 600 * 1500mm |

| 12 | Total equipment weight | About 1.5T |

IV、Rod feeding device

It is mainly used to clamp the preform and complete the functions of feeding the preform during the fiber drawing process. Specific technical indicators are as follows:

| 1 | Diameter of prefabricated parts | 10-40mm |

| 2 | Length of preform | 200-500mm (excluding the length of hidden rod) |

| 3 | Rod feeding speed | 0.05-10mm/min |

| 4 | Rapid lifting speed of rod feeding | ≥ 350mm / min |

| 5 | Rod feeding stroke | 400 mm |

| 6 | Rod feeding accuracy | ≤± 1 mm / 400mm |

| 7 | X-Y adjustment stroke | ± 12mm |

| 8 | Speed range and accuracy of preform rotation control | range: 0-1000rpm, accuracy: ≤± 10rpm |

Rod feeding device diagram (for reference)

The rod feeding mechanism is composed of a precision AC servo motor, a planetary precision reducer with a large speed ratio, and a high-precision ball screw.

Precision ball screw and two linear guide rails ensure the precise work of rod feeding.

V、Positive and negative pressure gas control system for preform

The system is mainly used to control the gas pressure of the preform. The preform can be filled and evacuated by welding and sealing. Specific parameters are as follows:

| 1 | Including one positive pressure and one negative pressure | |

| 2 | Positive pressure range | 0 ~ 100 kPa |

| 3 | Negative pressure range | 0 ~ - 1.3 kPa |

| 4 | Positive and negative voltage accuracy | not more than 1% |

浙公网安备33018302001591号ICP备案编号:浙ICP备2022013385号-2

浙公网安备33018302001591号ICP备案编号:浙ICP备2022013385号-2