客服电话

0571-63599807

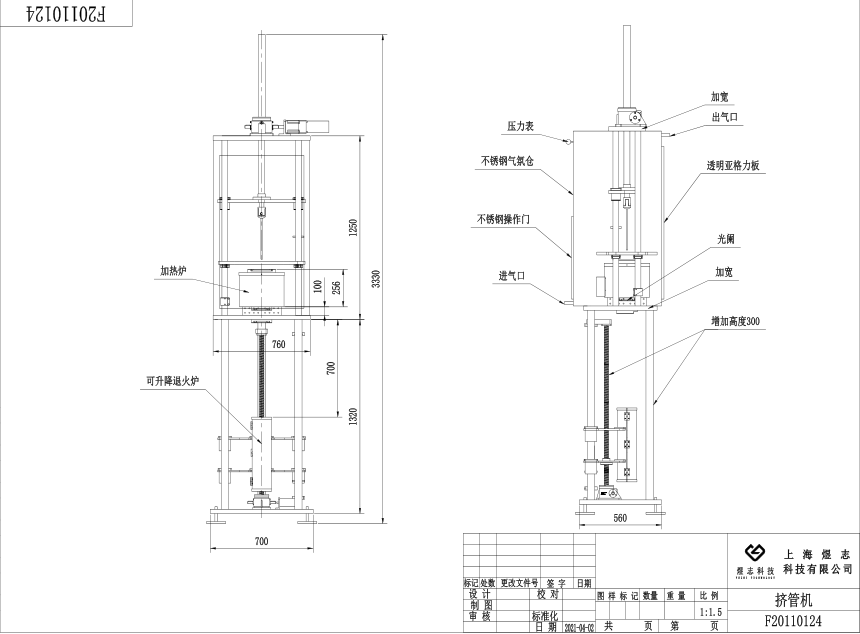

I、System structure drawing

II、Physical picture of appearance

III、Product Features

1. The fully sealed isolation chamber is adopted, and the heating and extrusion actions are completed in the isolation chamber. The high-precision adjustable diaphragm module is adopted at the interface;

2. Melting and annealing adopt full program control temperature rise and fall heating system, with fast temperature rise and fall speed, adjustable temperature and high temperature control accuracy;

3. The extrusion adopts servo mechanism, with high control accuracy, stable operation, no shaking, shaking, etc;

4. The lower annealing system uses a servo motor to drive the lead screw to move up and down, with adjustable speed and no shaking and shaking;

5. The overall structure is welded with profile steel, with high-temperature baking paint on the surface and leveling mechanism installed at the bottom. The overall installation is stable;

6.10-inch human-computer interaction interface, with intuitive functions, can compile and modify the temperature process curve through the touch screen, which is used to operate the temperature rise and fall of the furnace body and annealing furnace, control the pressurization speed, distance and other functional operations, record, save and export the historical curve, facilitate query, intelligent operation, and manual / automatic switching;

7. Non standard customization is acceptable.

IV、Product Parameters

|

No. |

System |

Part |

Parameter |

|

1 |

Heating Furnace |

Furnace size |

Ø150×130mm |

|

2 |

Heating power |

~4kW |

|

|

3 |

Maximum temp |

1000℃ |

|

|

4 |

Long operation temp |

<800℃ |

|

|

5 |

Temperature control accuracy |

±1℃ |

|

|

6 |

Temperature field unity |

±5℃ |

|

|

7 |

Annealing furnace |

Furnace size |

Ø50×500mm |

|

8 |

Heating power |

~2kW |

|

|

9 |

Maximum temp |

600℃ |

|

|

10 |

Long operation temp |

<400℃ |

|

|

11 |

Temperature control accuracy |

±1℃ |

|

|

12 |

Temperature field unity |

±5℃ |

|

|

13 |

Pressing part |

Pressure range |

0-1.8T |

|

14 |

Moving distance |

0-450mm |

|

|

15 |

Screw tension and pressure sensor |

20kN |

|

|

16 |

Moving part |

Trip |

0-1000mm |

|

17 |

Electrical and Temperature control |

10 inch color LCD touch screen, PID intelligent control, historical curve can be exported by USB to the computer for viewing, printing and storage. Integrated circuit, imported high-power module control, 30 sections of program programming, each section can be independently limited, and various heating, insulation and cooling programs can be prepared, with high temperature control accuracy; Multi interface display of main control screen, process curve, man-machine dialogue programming, fully automatic operation, no need for manual supervision (automatic temperature rise, heat preservation and temperature drop) |

|

|

18 |

Protecting system |

Double circuit protection: sound and light alarm such as deviation protection, over-heating protection, leakage protection and disconnection protection; Up and down travel switch + hard limit double combination |

|

浙公网安备33018302001591号ICP备案编号:浙ICP备2022013385号-2

浙公网安备33018302001591号ICP备案编号:浙ICP备2022013385号-2